Carbon nanotube products

Packaging

Jar 0.4 L (up to 100 g)

Another packaging volume is available at customers’ request

Versatile conductive additive based on polyol ester carrier to produce masterbatches for polypropylene (PP), thermoplastic polyurethane (TPU), filled phenyl polysulfide (PPS), acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), PC-ABS, polyamide (PA), glass-fiber reinforced polyamide resin (GF PA).

Resulting masterbatches can be used for compounding in filled polymers or in combination with other conductive fillers to reduce their content and gain better mechanics/fluidity.

Material system

Polypropylene (PP), thermoplastic polyurethane (TPU), filled phenyl polysulfide (PPS), acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), PC-ABS, polyamide (PA), glass-fiber reinforced polyamide resin (GF PA)

Working dosage

0.2–2 wt.%

Сoncentrate carrier

Polyol ester

Shape

Pellets

Benefits

Electrical conductivity

Permanent and homogeneous electrical conductivity at low dosages

Mechanical properties

Maintained original key mechanical performance

Permanent characteristics

Resistivity is independent of humidity

Less rejection

Less rejected final parts

Cases

E-painting

click to view case

News

October 31

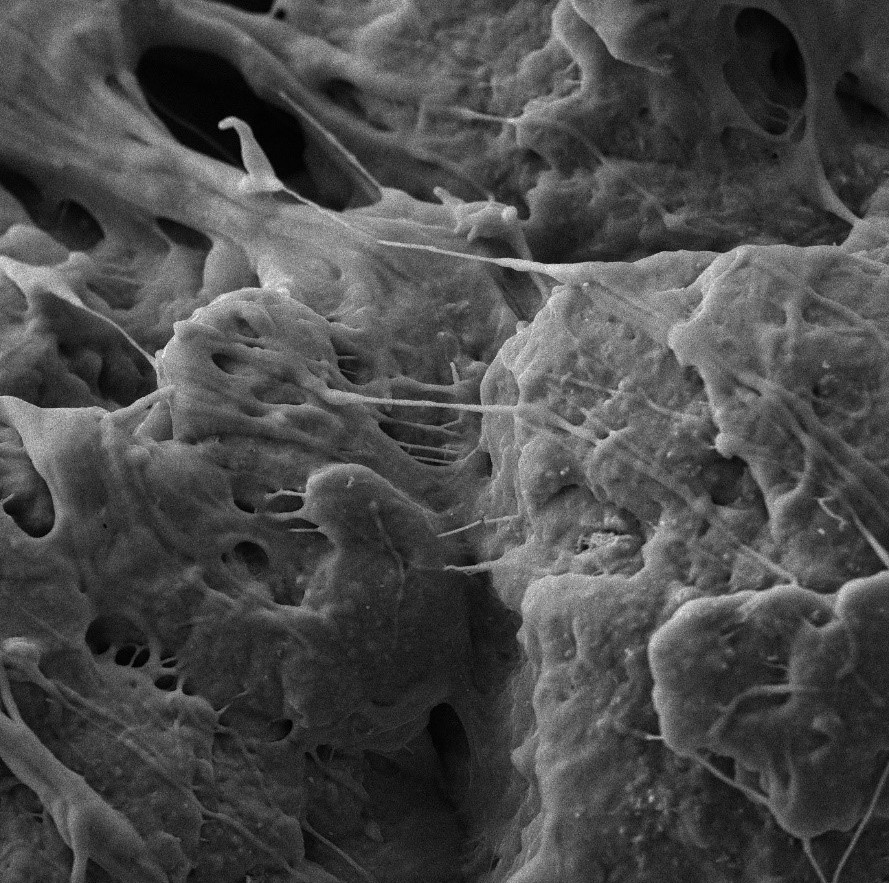

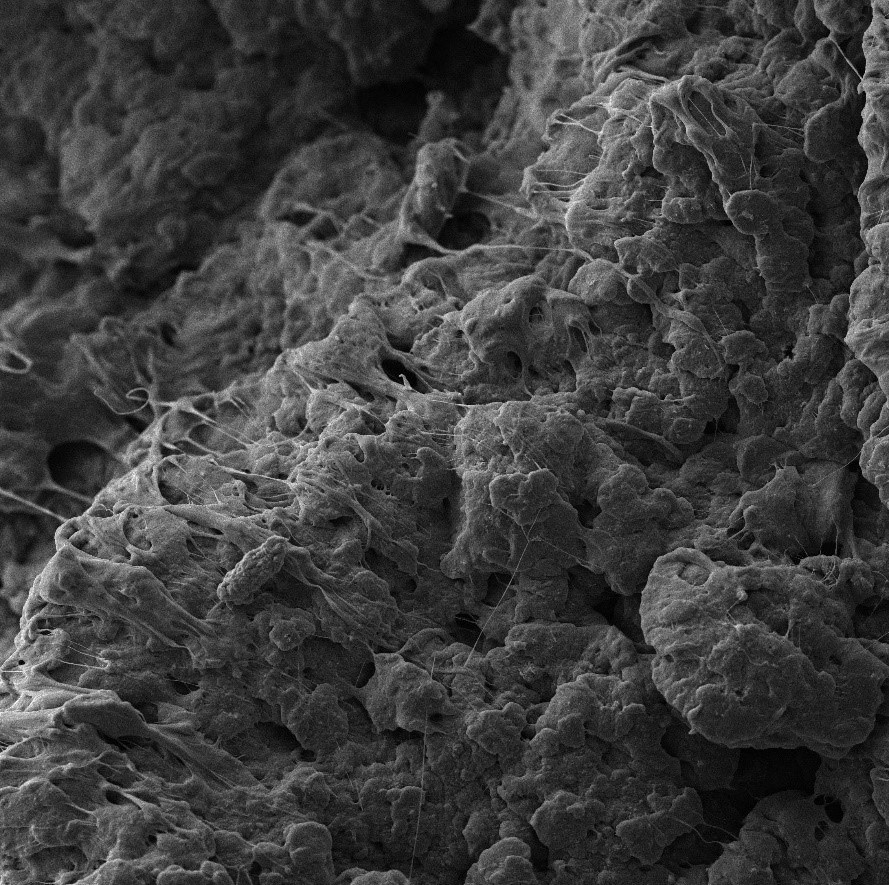

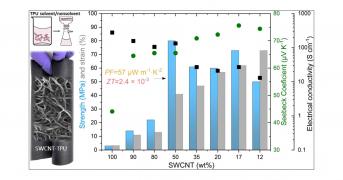

[💡R&D] Easy-to-process flexible thermoelectric materials with robust mechanical properties were developed by researches from National Research Council Canada and Leibniz-Institut für Polymerforschung Dresden. TUBALL–TPU nanocomposite shows ∼7-, 25-, and 250-fold improvements in stiffness, strength, and tensile toughness, respectively. These easily processed, self-supporting, and stretchable materials can be utilized for energy-harvesting modules based on the thermoelectric effect.

Read the article in full here: https://pubs.acs.org/doi/full/10.1021/acsanm.3c03247

Learn more on graphene nanotube uses and applications: https://tuball.com/nanotubes-for?utm_source=facebook+&utm_medium=Post+campaign&utm_campaign=Oct+31%272023

#TEG #composites #TPU

Read on Facebook

July 13

[🤔 #Didyouknow?] The first car bumper appeared in 1897 for aesthetic purposes. In 1901, it was redesigned to protect vehicle parts and ensure road safety. Initially made of rubber, most bumpers are now made of plastic. To achieve consistent color, manufacturers prefer to use electrostatic painting for both metallic and plastic parts. To do this, first a conductive primer should be applied on plastic parts to enhance the adhesion of the paint. Graphene nanotubes enable the production of light-gray conductive primers with high transfer efficiency for use in e-painting. This leads to cost optimization and reduced basecoat consumption compared to black primers.

Learn more on graphene nanotubes for automotive primers: https://tuball.com/nanotubes-for/conductive-primers?utm_source=Facebook&utm_medium=Post&utm_campaign=Did+you+know+Primer+July+23

#ElectrostaticPainting #Nanotubes #CarBumper

Read on Facebook

July 5

A signal lamp allows a miner to raise an alert and to be found in emergency situations. With graphene #nanotubes incorporated inside the #ABS case, the case of the lamp becomes anti-static, making it safe for use in hazardous areas like coal mines, where flammable gases or combustible dust can accumulate. By preventing the buildup of electrostatic charge, this modified lamp eliminates the risk of sparks and potential explosions.

Learn more on electrically conductive agent for thermoplastics: https://tuball.com/nanotubes-in/thermoplastics

Read on Facebook