13. Juni

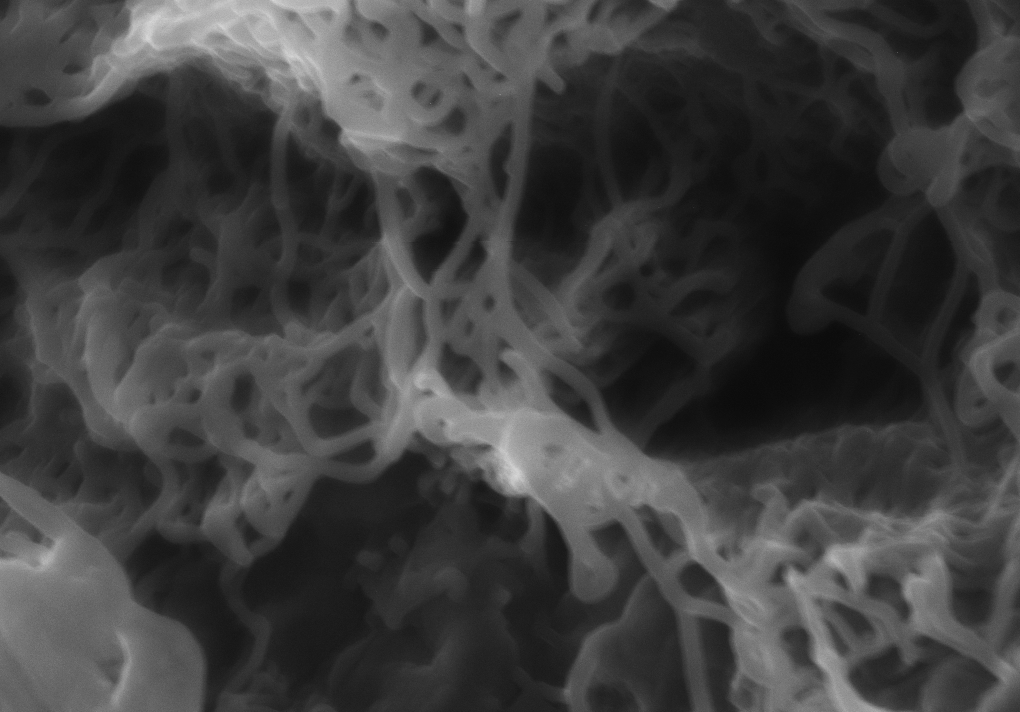

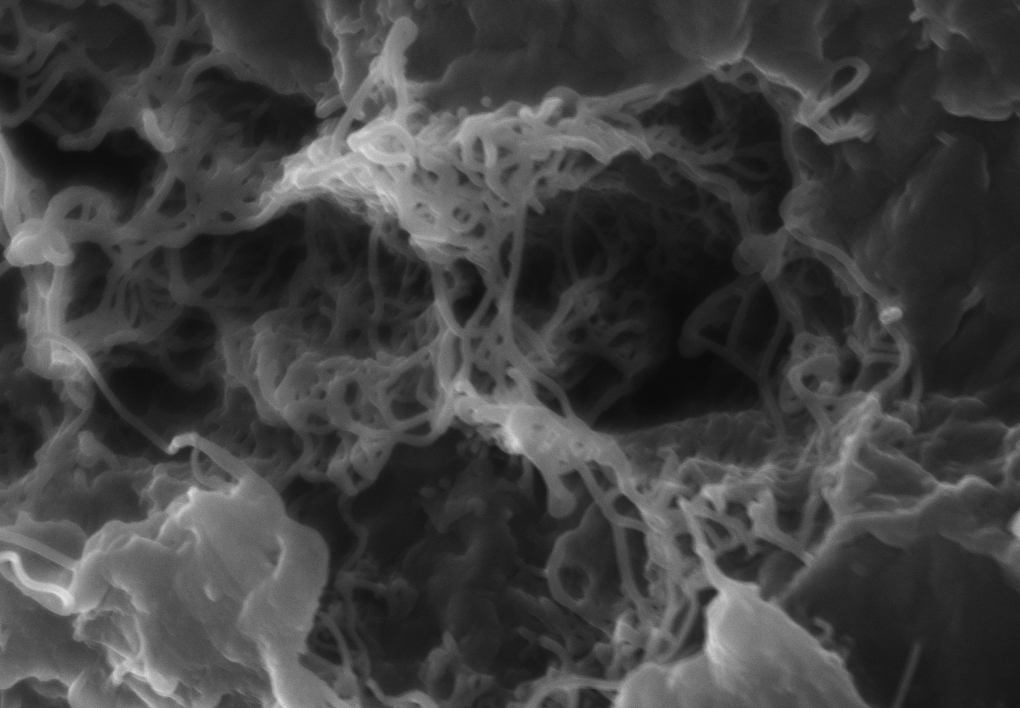

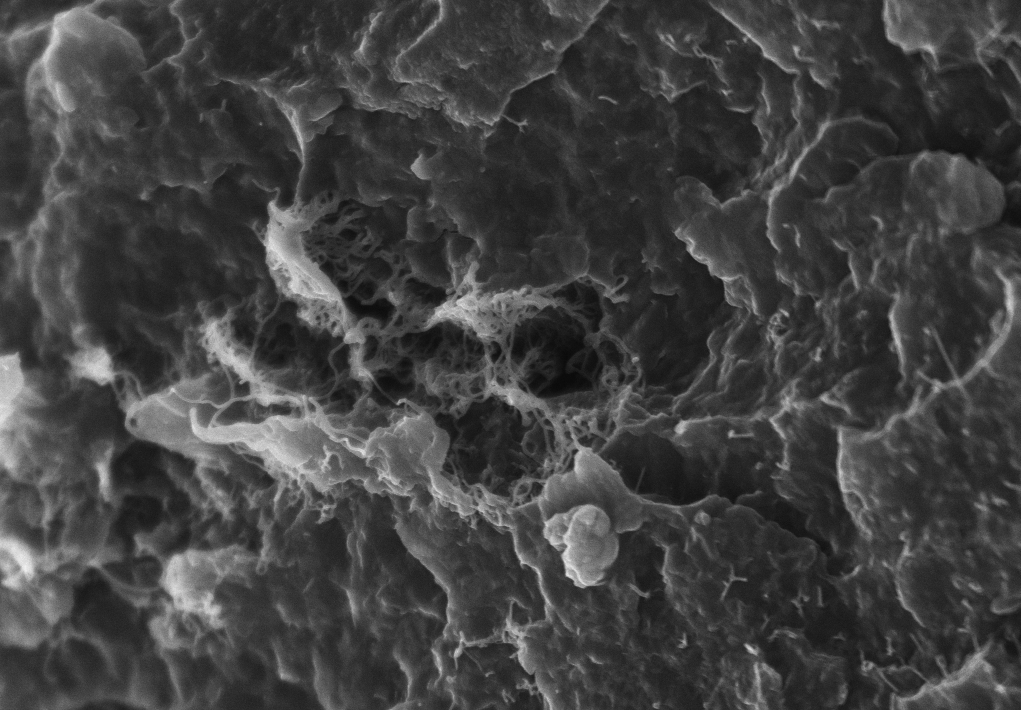

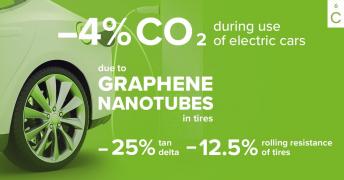

[#BreakingNews] 🚀 OCSiAl has completed a 3,000 MT single wall carbon nanotube water-based dispersion production site in Serbia, Europe! 🌍 This new facility will support various EV and consumer electronics projects by boosting the performance of Li-ion battery cells with energy-dense, silicon-rich, or fast-charging graphite anodes. 🔋✨ Scheduled to commence commercial production in the third quarter of 2024, this facility serves as an industrially scalable unit for SWCNT dispersion production and will be replicated by OCSiAl elsewhere in Europe, Asia, and the US.

Read the news in full: https://ocsial.com/news/ocsial-completes-single-wall-carbon-nanotube-dispersion-site-in-europe/

Learn more on graphene nanotube applications and uses: https://tuball.com/nanotubes-for?utm_source=facebook&utm_medium=Dispersion+site+in+Serbia+press-release&utm_campaign=June+13

#dispersions #ProductionSite #EV #batteries

Lesen Sie weiter auf Facebook