Compliance with modern ESD international requirements is a challenge for manufacturers. They set high standards: anti-static gloves must have a stable and humidity-independent electrical resistance.

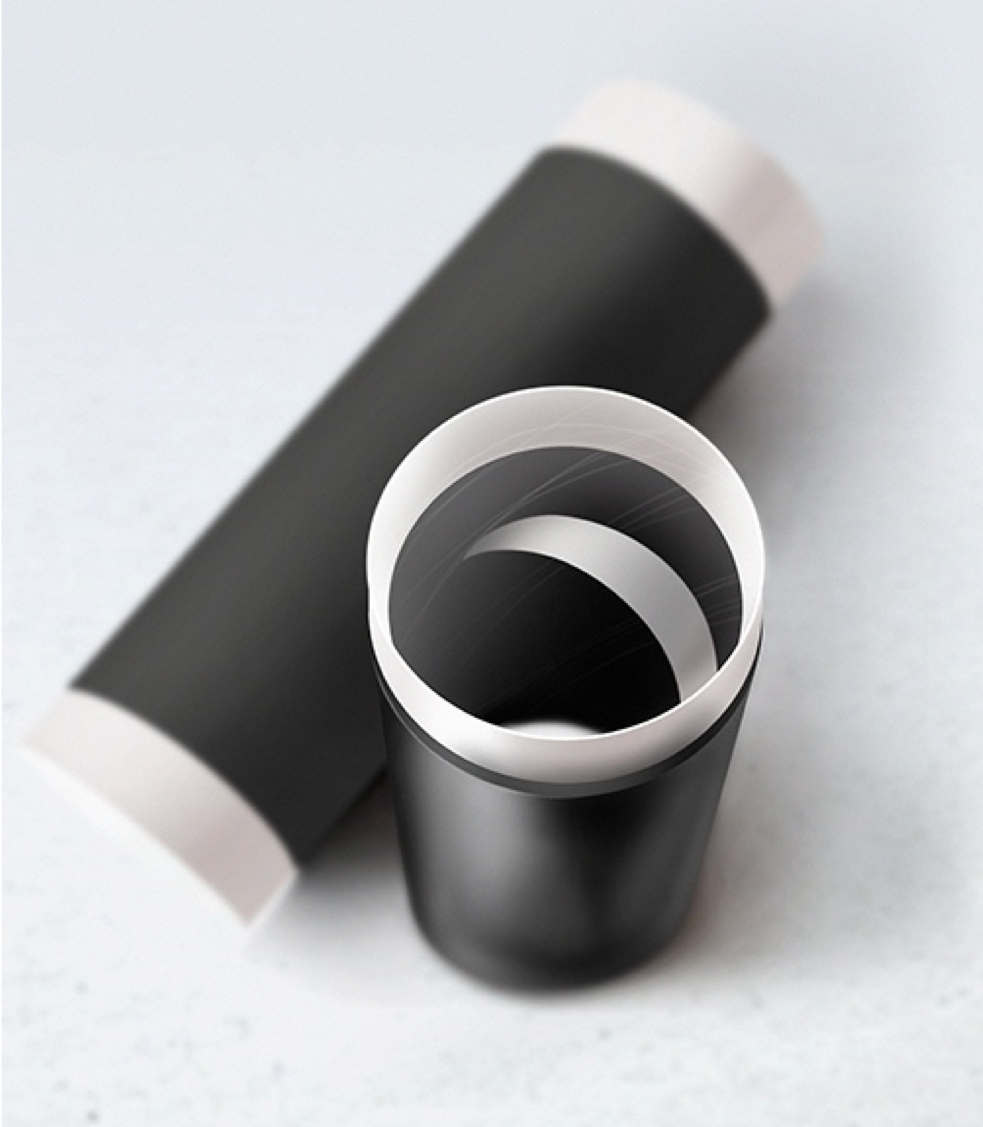

Graphene nanotubes are a unique anti-static agent, providing strong ESD protection to workers and static-sensitive equipment when used in all types of latex gloves.

With effective concentration starting from 0.05% graphene nanotubes provide stable and uniform conductivity, and also maintain mechanical properties of latex and allow coloration of end-products.

Gloves with nanotubes are used in hazardous environments and static-sensitive facilities in mining, chemical, electronics and automotive manufacturing, cleanrooms, and oil & gas industry.