31 de octubre

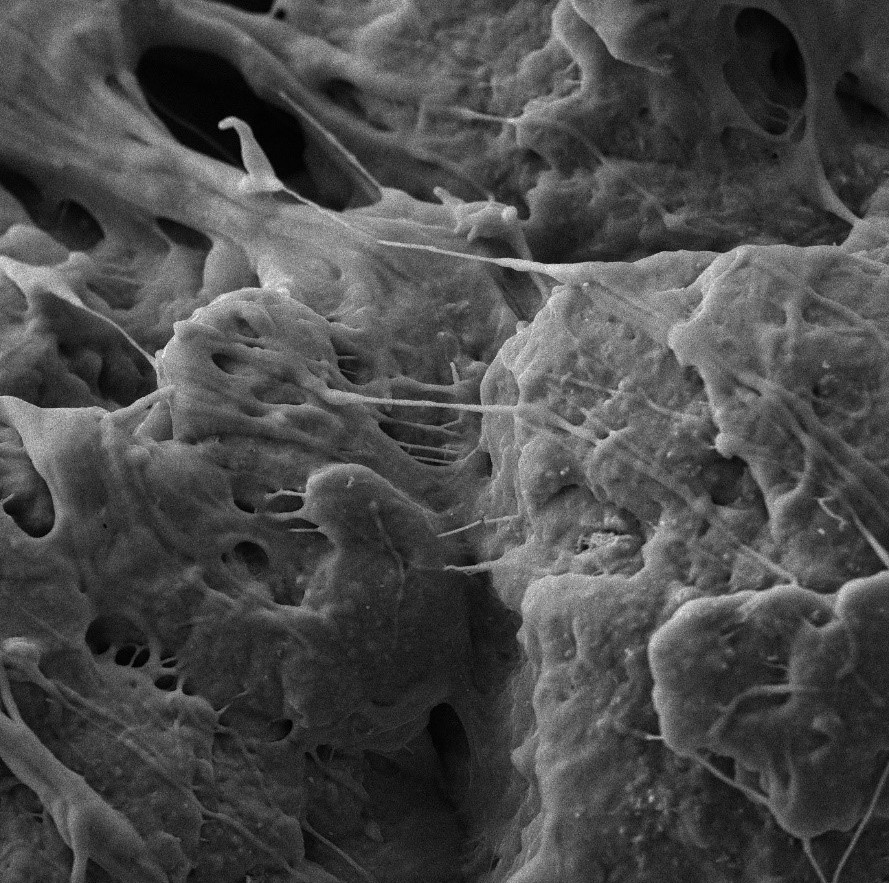

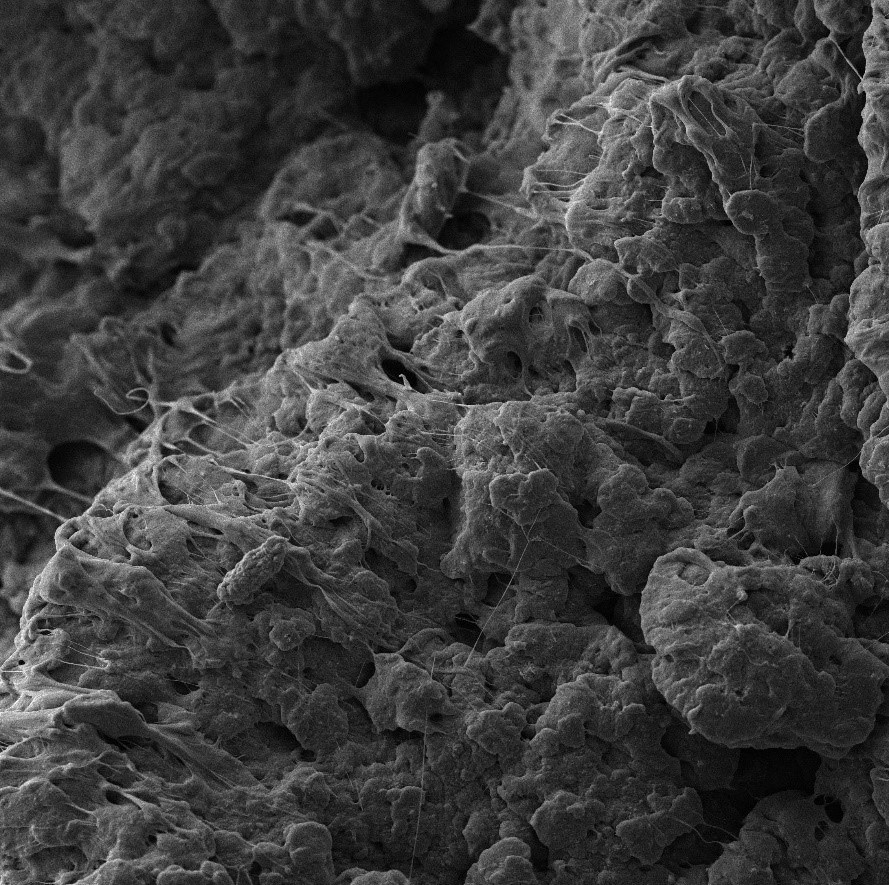

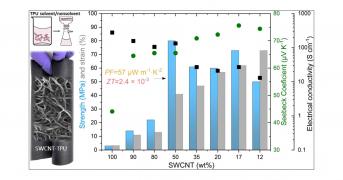

[💡R&D] Easy-to-process flexible thermoelectric materials with robust mechanical properties were developed by researches from National Research Council Canada and Leibniz-Institut für Polymerforschung Dresden. TUBALL–TPU nanocomposite shows ∼7-, 25-, and 250-fold improvements in stiffness, strength, and tensile toughness, respectively. These easily processed, self-supporting, and stretchable materials can be utilized for energy-harvesting modules based on the thermoelectric effect.

Read the article in full here: https://pubs.acs.org/doi/full/10.1021/acsanm.3c03247

Learn more on graphene nanotube uses and applications: https://tuball.com/nanotubes-for?utm_source=facebook+&utm_medium=Post+campaign&utm_campaign=Oct+31%272023

#TEG #composites #TPU

Leer en Facebook