Graphene nanotubes for glass fiber filled polyamide compounds: conductivity and maintained mechanical properties

TUBALL™ MATRIX 822및 TUBALL™ MATRIX 808형태의 TUBALL™ 그래핀 나노튜브는 폴리올 에스테르 캐리어 기반의 다목적 전도성 첨가제입니다. 열가소성 재료에 우수한 전기 전도성을 제공하는 동시에 기계적 특성을 유지하고 유리 섬유 충전 화합물의 MFI 레벨을 유지하도록 특별히 설계되었습니다.

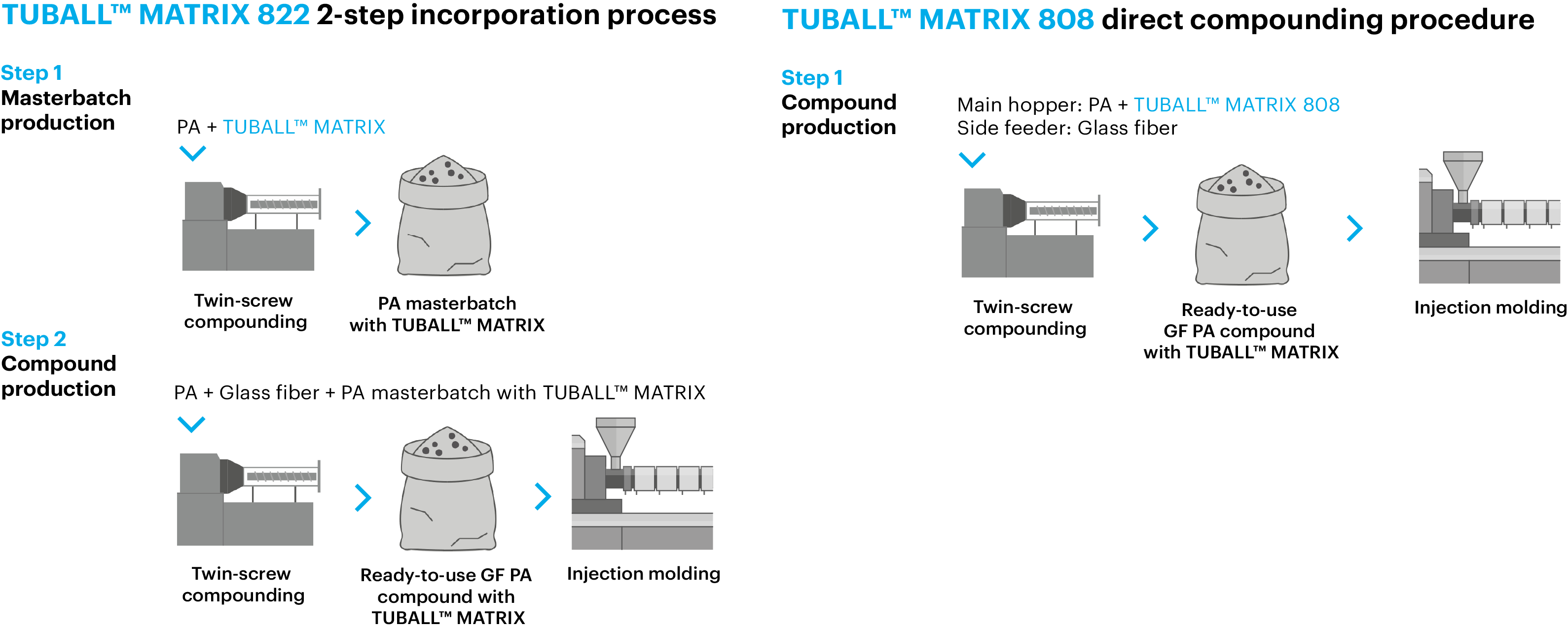

TUBALL™ MATRIX 822는 2단계로 통합되며 PA를 기반으로 마스터 배치를 생성할 수 있습니다. 생산된 마스터 배치는 충진된 중합체(filled polymer) 내의 배합 또는 다른 전도성 충진제(conductive filler)와 사용하여 함량을 줄이고 더 나은 기계적 특성 및 유동성을 얻기 위해 사용될 수 있습니다.

TUBALL™ MATRIX 808은 그래핀 나노튜브 함량이 더 적고 한 단계(직접 합성)로 통합될 수 있습니다.

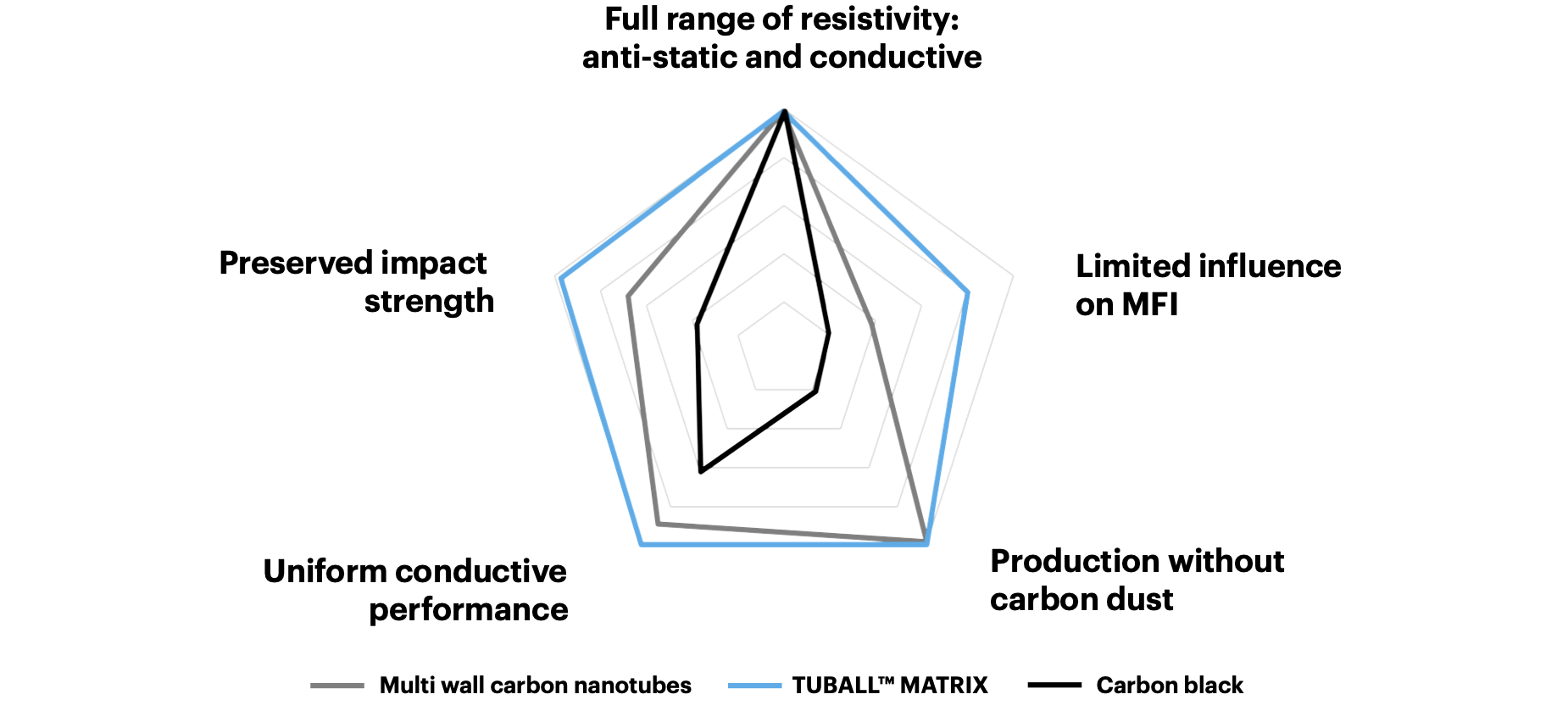

CONDUCTIVE ADDITIVES FOR GLASS FIBER FILLED PA: TRADITIONAL VS TUBALL™

Note. This diagram is based on an average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

Benefits provided by TUBALL™ nanotubes for GF-filled PA:

- Ultra-low dosage starting from just 0.05 wt.% TUBALL™ graphene nanotubes*

- Maintains good balance of mechanical properties

- Enables a new combination of GF-filled PA properties in comparison to standard conductive agents

- Permanent, stable and uniform electrical resistivity without “hot spots”

- Stable performance reducing the number of out-of-spec parts

- Good processability and easy handling

- Allows production of conductive parts that retain colors

*Dosages may vary depending on the formulation, processing, and products.

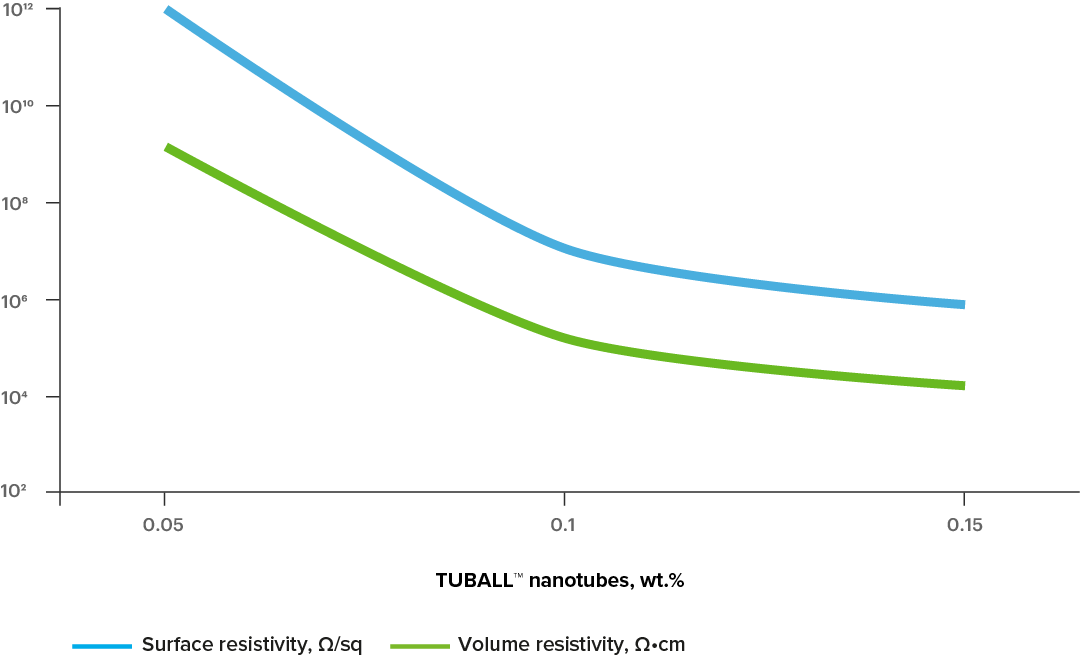

FULL RANGE OF RESISTIVITY

Graphene nanotubes’ unique morphology allows them to create a dense conductive network inside thermoplastic compounds at ultra-low loading rates—starting from just 0.05 wt.% in the total compound.

30% glass fiber filled polyamide compounds. Injection molded samples. Surface resistivity: ASTM D257. Volume resistivity: ASTM D4496.

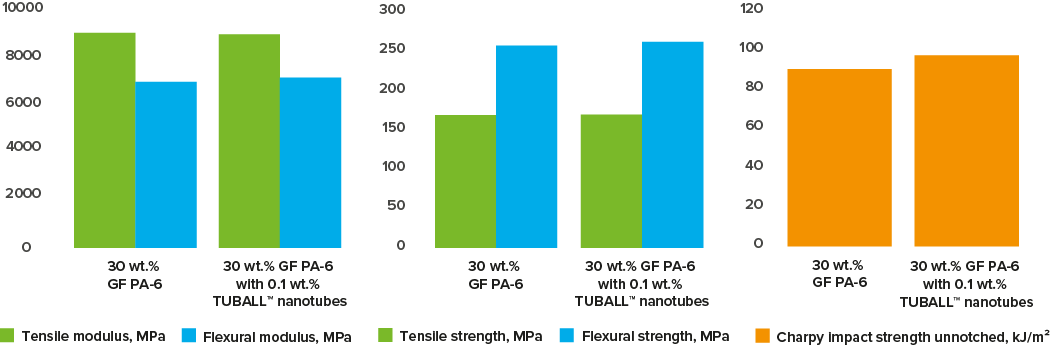

MAINTAINED MECHANICAL PROPERTIES

The usage of TUBALL™ MATRIX preserves key mechanical properties in comparison to other conductive additives.

30% glass fiber filled polyamide-6 compounds. Injection molded samples. TUBALL™ was applied via TUBALL™ MATRIX 822. Impact strength: ISO 179; Tensile performance: ISO 527; Flexural performance: ISO 178.

EASY TO APPLY WITH STANDARD EQUIPMENT

TUBALL™ MATRIX can be processed with standard equipment widely used in the thermoplastics industry.

PA enhanced with TUBALL™ graphene nanotubes has found wide usage in the automotive e-painting, automotive safety, ESD materials and ATEX applications.

Pay close attention to the processing guidelines for TUBALL™ MATRIX

Download PDF version:

응용 분야

E-painting

TUBALL™ MATRIX for glass fiber filled polyamide

추가 정보

How to grant conductivity to glass fiber reinforced polyamide: compounding guide

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample