CATHODES

Carbon atoms can bond together in various ways, resulting in a number of allotropic forms of carbon with different physical properties. The known allotropes include graphite, diamond, fullerenes, nanotubes and graphene. The last three are mostly artificial.

Their origin, morphology and method of production affect the properties that these carbon allotropes grant to materials when they are used as an additive, and this differs a lot from one form of carbon to another. Graphene and nanotubes have the best combination of properties and benefits.

|

Single-walled carbon nanotubes (SWCNTs), also called graphene nanotubes (GNTs) |

Graphene |

Multi-walled carbon nanotubes (MWCNTs) |

Nanographite structures |

Graphite structures |

|

|

|

|

|

|

A graphene layer seamlessly rolled into a tube |

A single sheet or monolayer of carbon atoms tightly bound in a hexagonal honeycomb lattice |

A concentric arrangement of SWCNTs, i.e. multiple layers of graphene seamlessly rolled into a concentric tubular structure |

Graphene flakes are small platelets of graphite; GO/RGOare few-layer nanoscale graphites, have oxygen groups or have undergone additional reduction |

A large set of multiple graphene sheets |

|

Industrial-scale production (hundreds of tonnes) |

Not designed as an additive to materials (production in kgs) |

Industrial-scale production (thousands of tonnes) |

Industrial-scale production (thousands of tonnes) |

Industrial-scale production (millions of tonnes) |

These carbon-based additives, with the exception of graphene, are produced at a scale of hundreds or thousands of tonnes and are available for industrial applications.

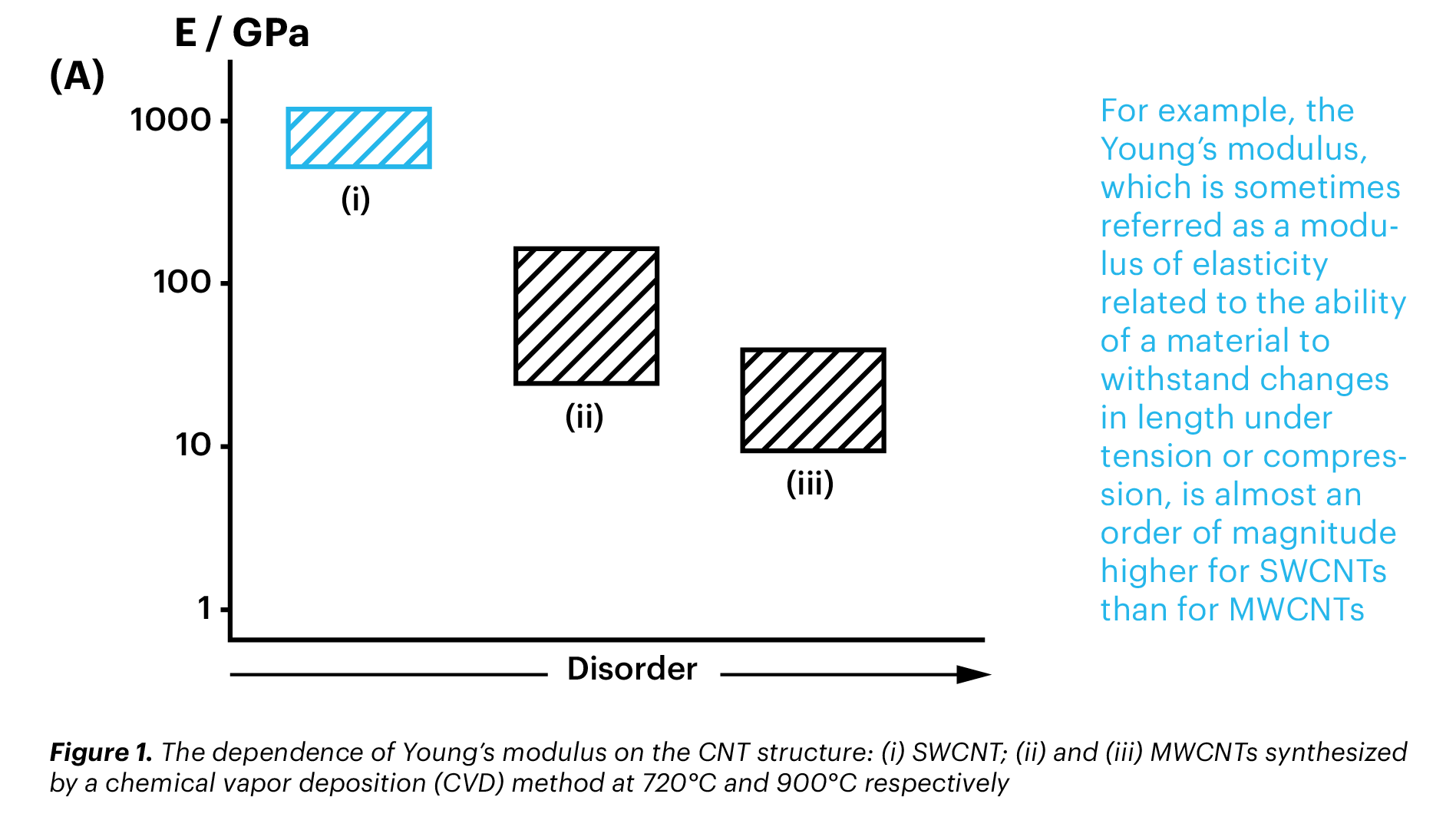

Carbon nanotubes fundamentally fall into two classes: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). Despite the obvious commonality, SWCNTs and MWCNTs have significantly different physical properties from each other because of their structural differences.

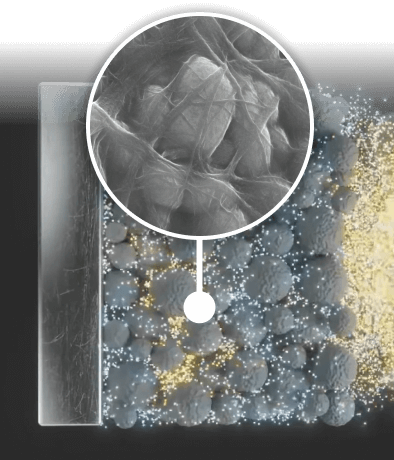

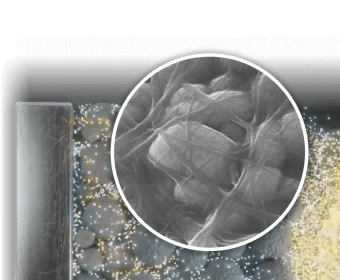

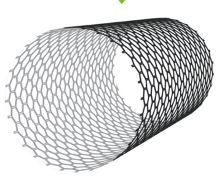

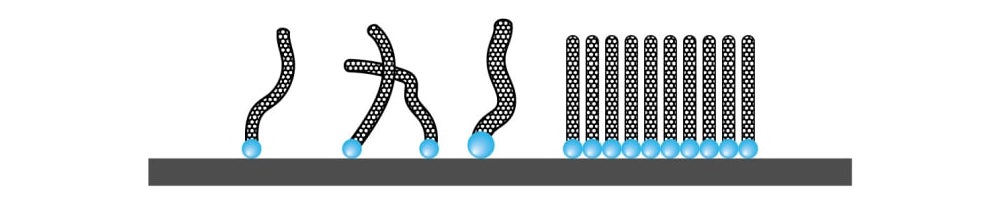

The most important feature that distinguishes SWCNTs is that the wall of the nanotube consists of the only one graphene layer. In other words, single-walled carbon nanotubes can be described as graphene sheets seamlessly rolled up to form hollow cylinders. That is why they often referred to as graphene nanotubes (GNTs).

Unlike a single-walled nanotube, a multi-walled carbon nanotube can be viewed as a concentric arrangement of SWCNTs, i.e. consisting of multiple layers of graphene rolled up seamlessly into a tube shape.

.png)

These differences between single-walled and multi-walled carbon nanotubes result in substantially different properties and corresponding impacts on materials after their introduction.

|

Parameter |

SWCNTs |

MWCNTs |

|

Key parameters |

||

|

Typical diameter |

1–2 nm* |

7–100 nm |

|

Typical length |

Up to 1 mm** |

Up to 1 mm |

|

Aspect ratio |

Up to 10 000 |

50–4000 |

|

Mechanical properties |

||

|

Elastic modulus |

1000–3000 GPa |

300–1000 GPa |

|

Tensile strength |

50–100 GPa |

10–50 GPa |

|

Electronic structure properties |

||

|

Thermal conductivity at 300K |

3000–6000 W/(m·K) |

2000–3000 W/(m·K) |

|

Minimum working dosage as an anti-static additive |

0.01% |

0.5% |

* Larger diameters are possible but could lead to an increased number of defects

** Longer lengths are possible but only at laboratory-scale

The diameter of SWCNTs is less than 2 nm, while for MWCNTs it is more than 10 nm and can be up to hundreds of nanometers.

Both types of carbon nanotubes can be grown to a length of a few hundreds of nanometers up to millimeters but typically they are in the range of 1–30 micrometers.

Because of their smaller diameter, SWCNTs typically have a higher length-to-diameter ratio, resulting in unprecedented flexibility. In fact, a number of the mechanical improvements that single-walled carbon nanotubes impart to materials can be attributed to this high aspect ratio.

Formation of a 3D conductive network can be achieved at ultra-low concentrations, starting from just 0.01% of the total weight. Such low concentrations have no negative effect on color.

Typical aspect ratios for MWCNTs are lower and thus the percolation threshold for conductivity is higher. Owing to their larger diameter, MWCNTs are very rigid and their asbestos-like behavior poses health risks.

Because of their high rigidity, MWCNTs cannot be easily bent, twisted, kinked, or buckled without damaging them, whereas SWCNTs are flexible and can return to their original structure with more ease.

The tensile strength and elastic modulus of SWCNTs are among the highest (~50 GPa and ~1000 GPa respectively), which makes them desirable for applications in strengthening various materials, including polymer composites.

Theoretically, an ideal dispersion of isotropically distributed SWCNTs in a polymer composite would achieve a 100 MPa increase in tensile strength for each 1 wt.% of SWCNTs added. In practice, the loading of SWCNTs needed for the required mechanical improvements can even be less than 0.2 wt.%.

For MWCNTs, loading concentrations of 3–5 % are typically required for improving mechanical properties. This results in deterioration of other important characteristics, such as the surface quality and color of the final product.

SWCNTs surpass MWCNTs in terms of thermal conductivity per unit mass and can be used as an additive for improving thermal conductivity. Both materials withstand high temperatures (up to 750°C at normal conditions).

SWCNTs have one layer of carbon atoms and exhibit either metallic or semiconducting properties depending on the chirality. Both types have their unique advantages and, upon separation, can be used in nanoelectronics. Even without separation, the high electrical conductivity of raw SWCNTs (which can be further improved by doping) allows the use of very low concentrations as an additive to improve electrical conductivity of composites.

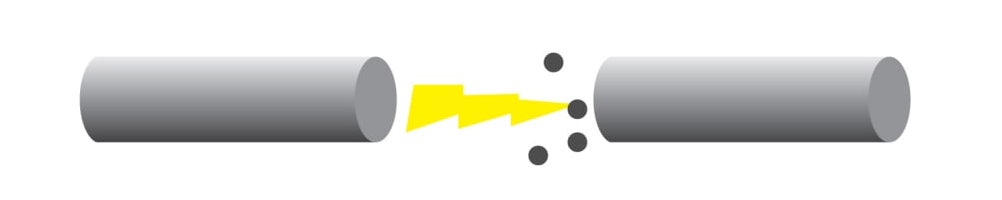

SWCNTs do not only have the highest electrical conductivity but, because of the strong carbon–carbon bonds, metallic SWCNTs can carry an electric current density over 1000 times greater than that in metals such as copper, where current density is limited by electromigration. In other words, SWCNTs have high ampacity.

Carbon nanotubes are widely applied as an anti-static additive in various materials. Electrical conductivity in these improved materials appears when the concentration of the conductive additive is higher than the so-called “percolation threshold”. The percolation threshold is inversely proportional to the aspect ratio of the filler, which is the highest for SWCNTs and their bundles. That is why optimally dispersed and distributed SWCNTs can enable dissipation of static electricity in materials at concentrations as low as 0.01%. Multi-walled carbon nanotubes require higher concentrations, more than 0.5%, to achieve a similar effect.

Thanks to their unique structural and physical properties, single-walled carbon nanotubes enable not only conductive properties but improve mechanical characteristics of materials and do so without negative health impacts and at lower concentrations, often without affecting the rheological properties and coloration of the final products.

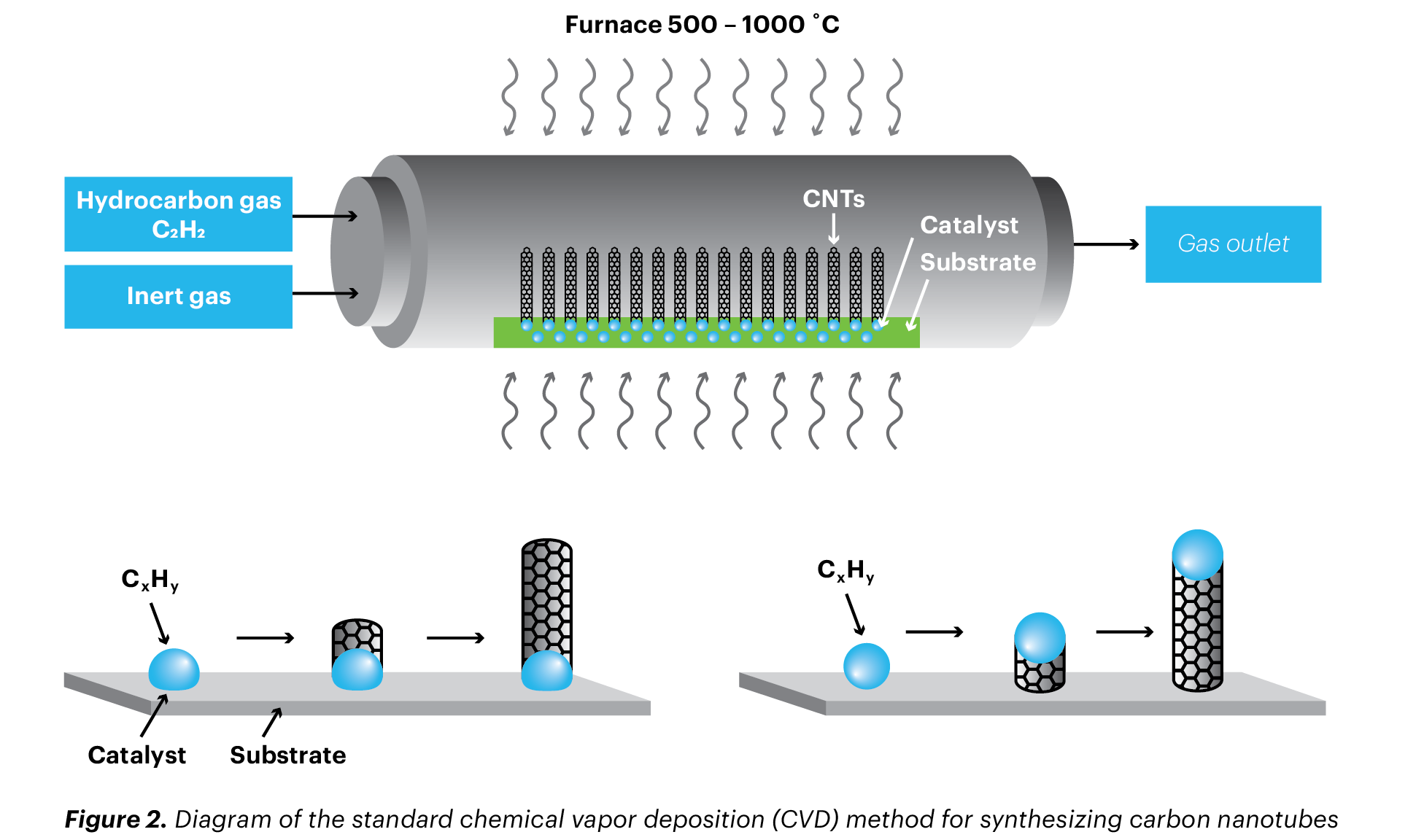

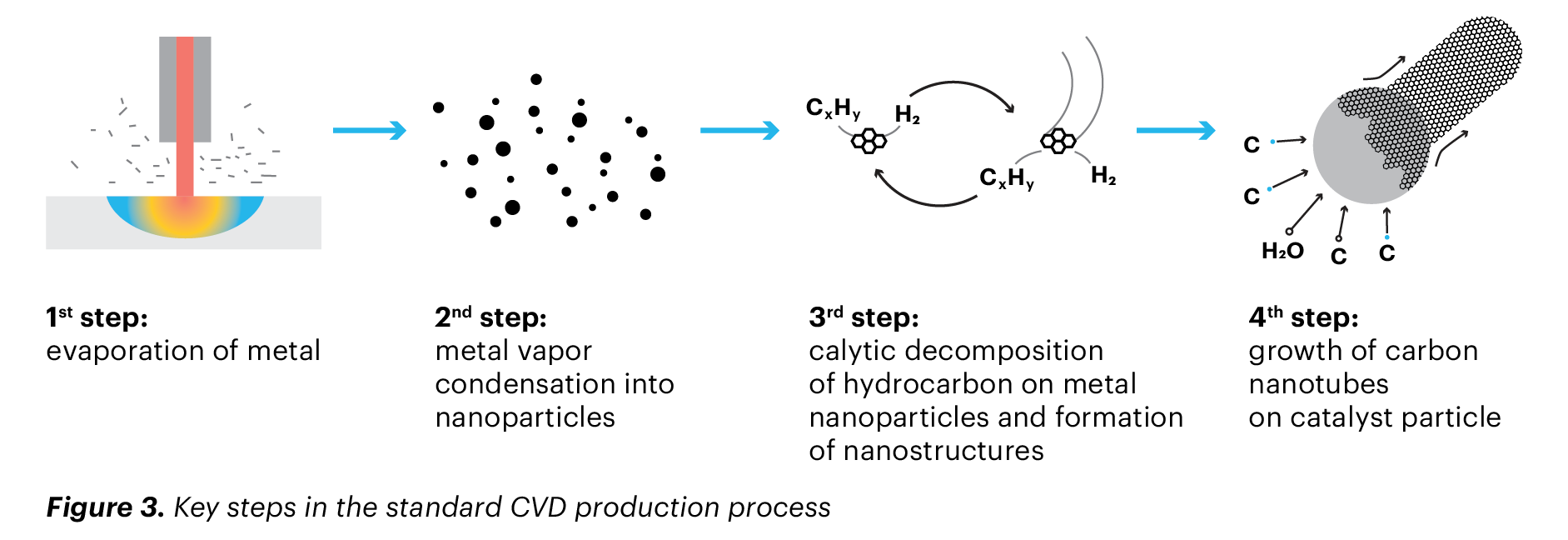

There are three main methods of nanotube synthesis:

• plasma arc discharge: production of carbon nanotubes in an arc discharge plasma in a helium atmosphere.

• plasma arc discharge: production of carbon nanotubes in an arc discharge plasma in a helium atmosphere. • laser evaporation (pulsed laser ablation): evaporation of a graphite target in a high-temperature reaction by the action of a pulsed laser.

• laser evaporation (pulsed laser ablation): evaporation of a graphite target in a high-temperature reaction by the action of a pulsed laser. • chemical vapor deposition (CVD): catalytic (nickel, cobalt, iron or their combinations) deposition of carbon from hydrocarbons (methane, ethylene, acetylene)

• chemical vapor deposition (CVD): catalytic (nickel, cobalt, iron or their combinations) deposition of carbon from hydrocarbons (methane, ethylene, acetylene)|

Method |

Arc discharge method |

Chemical vapor deposition |

Laser ablation |

|

Process |

Between two graphite rods a few millimeters apart, under high current (~100 A), carbon vaporises and forms a hot plasma |

Heated up to 1000°C in an oven with/without a substrate, carbon-bearing gas such as methane decomposes on a catalyst into carbon nanotubes |

Graphite under intense laser pulses evaporates and forms the carbon nanotubes |

|

Typical yield |

30–90% |

50–100% |

Up to 70% |

|

SWCNTs |

Short tubes with diameters of 0.6–1.4 nm |

Long tubes/bundles (up to 40 micrometers) or bundles with individual diameters of 0.6–2 nm |

Long bundles of tubes (5–20 micrometers), with individual diameters of 1– 2 nm |

|

MWCNTs |

Short tubes with inner diameter of 1–3 nm and outer diameter ~10 nm or more |

Long tubes with external diameters of 10–240 nm |

Typically, yield of MWCNTs is low. Characteristics vary significantly. |

|

Production |

Nanotubes tend to be short with random sizes; substantial purification is needed |

Commercially the most developed method, easiest to scale up, good yield and quality control, high-purity SWCNTs |

Not considered a commercially viable technique because it requires expensive lasers and it does not very good yield per power |

|

Defects |

Large quantities of impure SWCNTs and MWCNTs are generally produced, and the. SWCNTs have structural defects |

MWCNTs are often riddled with defects compared with SWCNTs, for which the quality is better controlled |

Laser ablation produces a small amount of CNTs, primarily SWCNTs, with good diameter control and which are quite pure and have few defects |

CVD is the most developed method for commercial production of CNTs.

This method also gives more flexibility in terms of diameter, length and morphology of nanotubes. Nevertheless, reproducibility often remains challenging.

Currently, OCSiAl is the leading manufacturer of SWCNT. The company produces high-quality single-walled carbon nanotubes at a scale of tens of tonnes annually, with plans to increase this to hundreds of tonnes.

The geometry of nanotubes is determined by the chiral vector of the original hexagonal lattice. The type of self-assembly of the SWCNT (its chirality) influences its electrical conductive properties, making it conductive or semiconductive.

The state of twisting for an SWCNT can be described by the “n” and “m” chirality indexes, which reflect the vector direction for rolling the hexagonal lattice into a tube.

The reduced electrical resistance that nanotubes grant to materials depends on the dosage, their length, and the proportion of conductive CNTs among the overall amount of nanotubes. Doping with SWCNTs allows the fraction of conductive (metallic) nanotubes to be increased by almost a factor of three.

.png)

SWCNTs are proving their great potential for utilization as a multifunctional additive and for creating new products with previously unattainable properties. They allow improvement of various features in practically all known materials: to impart conductive and anti-static properties, and to increase strength, crack resistance, flexibility and adhesion, and many other parameters depending on the required application. Moreover, this is often achieved at SWCNT concentrations of tenths or hundredths of a percent, which generally makes it possible to retain the existing technologies for manufacturing the end products.

There are several approaches to classification of SWCNT applications. The most common are by the industry, material or type of industrial product. Classification by the type of industrial product can also be further classified depending on the potential volume of SWCNT consumption.

Composite materials and reinforced plastics, industrial coatings, car tires and rubber technical goods, structural materials, and materials for electrochemical power sources account for the most significant volume of SWCNT consumption. The next group of applications in terms of the volume of SWCNTs used includes adhesives and lubricants, anti-static plastics, transparent conductive films, and cables. Then there are a few niche applications that use limited quantities of single-walled carbon nanotubes.

SWCNTs are entering this market with a primary focus on applications in alternative energy and infrastructure (pipes, elements of building structures), and in automotive and aircraft structural materials. These industries require lightweight and strong materials with improved physical properties (blades of wind power generators, boat hulls, aircraft parts, vessels, etc.). The number of solutions to increase the strength of composite materials using SWCNTs is steadily increasing 2, 3.

These plastics are extensively used in many industries that have markets amounting to billions of dollars and that are experiencing considerable growth. The increasing use of SWCNTs in reinforced plastics is mainly due to the needs of the automotive industry, which is to reduce fuel inputs or battery load through reduction of weight of all car components, and the aerospace industry, which, in addition to weight reduction, needs materials that are able to resist extreme conditions and loads. All these challenges can be solved using single-walled carbon nanotubes4.

In this field, single-walled carbon nanotubes are used as a multifunctional additive for primers and paints designed for vehicle coatings (bodies of cars, aircraft, boat hulls, etc.), equipment (electrical and household appliances) and storage containers/vessels5, 6, 7 as well as for anti-static floors8. SWCNTs can be applied in more than half of the products in the vast market of industrial coatings.

The application of SWCNTs in tires allows significant improvement in their stiffness, tear resistance, fuel efficiency and grip9. This improvement is achieved at very low concentrations, with no additional changes required to the existing production technologies. SWCNTs can impart the required electrical conductivity to tires without any other conductive filler (e.g. without carbon black). The potential application of SWCNTs is estimated at 30% in the premium segment and at about 10% in the standard tires segment.

The use of SWCNTs in electrochemical power sources has been shown to be beneficial in virtually 100% of the available technologies. The main segments in this market are rechargeable power sources, lithium-ion batteries for electric vehicles, as well as batteries for laptops and mobile phones, and alkaline cells. Their inclusion in battery electrodes makes it possible to significantly improve target parameters such as storage density and cyclability that have a direct impact on the service life of power sources10.

Single-walled carbon nanotubes provide technological advantages to products based on a wide range of rubbers, silicones and thermoplastic elastomers. While improving the strength and elastic properties of rubber composites, SWCNTs also allow retaining and, in certain cases, enhancing other important properties such as Shore hardness, cohesive strength, dynamic strength, resistance to abrasion, reduction of hysteresis losses and retention of product colors11. SWCNTs have potential to be used in about one-third of rubber technical goods.

In materials such as bitumen12, asphalt13 and metal-based composite materials14, SWCNTs allow control of the structural features of the material while providing improved performance properties.

In this industry, solutions with single-walled carbon nanotubes are being developed as hazardous gas and toxin detectors and in gas and liquid filtration systems. Once readymade market solutions become available, SWCNTs might be used in 3–5% of such products.

Owing to their chemical compatibility with biomolecules (DNA and protein), single-walled carbon nanotubes can be used as components of biosensors and medical equipment. Tests of SWCNTs in implants show that they can be further used as coatings for catheters and neural implants. Solutions are also being developed for application in vivo, in particular for targeted delivery of substances encapsulated in SWCNTs16.

SWCNTs are strong but elastic and have excellent electronic properties. Therefore, they can be used in many applications in electronics, such as smart textiles, transistors, RFID chips, information storage devices, integrated circuits and CMOS batteries.

The above examples are not exhaustive in terms of the variety of SWCNT applications. Overall, adding SWCNTs can change 70% of the currently existing materials, which is equivalent to a market of about $3 trillion. Successful laboratory results and patents have been obtained in respect of many applications.

The launch of mass production of SWCNTs has made it possible to introduce laboratory results into industrial technologies and has enabled the manufacture of mass products. As the production volume of single-walled carbon nanotubes increases and their unit price decreases, their scope of application will expand even further.

In contrast to other carbon nanomaterials, single-walled carbon nanotubes have high flexibility, according to the German Federal Institute for Occupational Safety and Health (BAuA), which means that they have a number of completely different features in terms of health & safety, and environmental considerations.

Assessments on specific SWCNTs have demonstrated that, due to their relatively large size, aerosol tests can not be carried out, allowing a conclusion that agglomerated SWCNTs can’t enter deep lung. SWCNTs show no rigidity, which is a result of their flexibility, and they have a propensity to reduce surface energy and a tendency to form bundles or agglomerates. The International Agency for Research on Cancer (IARC) has classified single-walled carbon nanotubes as a substance “unclassifiable as to carcinogenicity in humans”18.

With respect to consumer exposure, there is assumed to be no risk as consumers only contact single-walled carbon nanotubes when they are incorporated in composite materials, mainly polymer-based. Once SWCNTs are used as a reinforcing or conductive material in polymer composites, they are highly agglomerated and surrounded by polymers. Thus they no longer have any nanoparticle characteristics, and even in cases where composite material is ground, cut or otherwise mechanically degraded, pure SWCNTs are typically not released, but only as a part of higher aggregated, polymer-bound particles. In conclusion, exposure of consumers to SWCNTs is extremely limited and they are not considered to pose any hazard to consumers, either by inhalation or by dermal or oral exposure19.

As pointed out by toxicologists20, unlike multi-walled carbon nanotubes and carbon fibers, single-walled carbon nanotubes are highly flexible and may thus generally have a lower potential to harm cell walls. A study on the effects of multi-walled carbon nanotubes on marine algae21 demonstrated both acute and chronic toxic effects of MWCNTs on marine algae21. A study performed with single-walled carbon nanotubes, found that there were no toxic effects after exposure of algae to SWCNTs22. It should be noted here that both studies were performed according to the same OECD test guideline 201.

In 2016, the EU’s REACH Regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals) registered single-walled carbon nanotubes as a new substance for the first time ever23.

In 2019, the US EPA (Environmental Protection Agency) published a SNUR in the Federal Register covering single-walled carbon nanotubes which authorizes unlimited nanotube sales up and down supply chain in the USA.