Carbon nanotube products

Packaging

Jar 0.4 L (up to 100 g)

Another packaging volume is available at customers’ request

TUBALL™ MATRIX 610 is a versatile masterbatch specifically designed for EPDM rubber compounds.

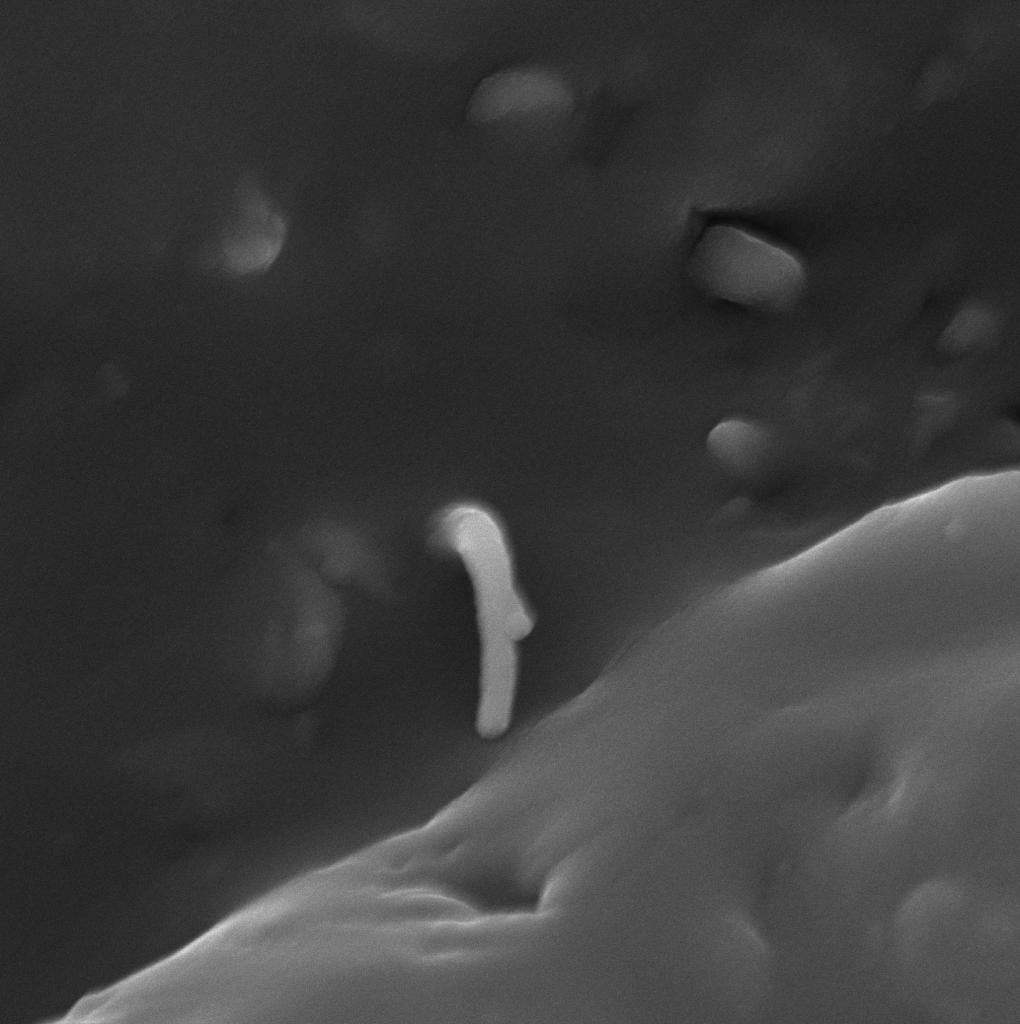

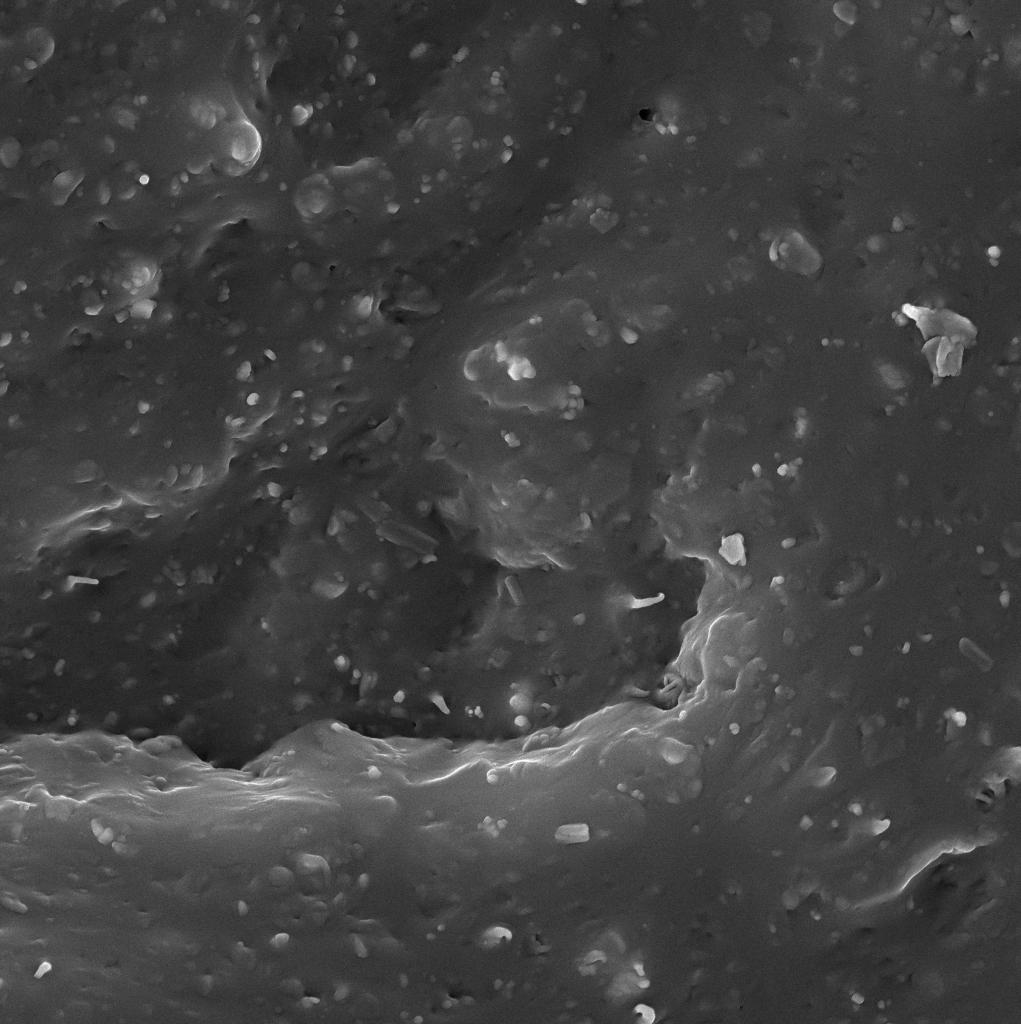

TUBALL™ nanotubes provide a permanent, stable level of electrical conductivity and improve the mechanical properties of various types of EPDM.

Material system

Rubber

Working dosage

3–6 wt.%

Сoncentrate carrier

Polymer, paraffinic mineral oil

Shape

Paste

Benefits

Electrical conductivity

Provides uniform, permanent electrical conductivity

Mechanical properties

- Improves a range of mechanical properties such as tensile modulus and tear strength by up to 70%

- Makes it possible to maintain a low hardness of compounds without losses in elastic behavior

Easy to use

- Allows use of standard processing and mixing equipment

- Carrier compatible with a wide range of EPDM grades, formulations and fillers

Retains сolor

- Allows coloration

- Non-marking compounds

Cases

EPDM cable accessories

click to view case

EPDM сonveyor Belts and Rollers

click to view case

Video

Anti-static colored EPDM rubbers - Processing guide

Conductive elastomers: Prevent negative trade-offs in mechanical properties and color due to SWCNT

Documents

Also available in:

English

TUBALL MATRIX 610 PROCESSING GUIDELINES ENG V03.PDF

PDF716.8 kB

TUBALL MATRIX 610 PROCESSING KEY POINTS ENG V01.PDF

PDF102.4 kB

TDS TUBALL MATRIX 610 ENG V05.PDF

PDF409.6 kB

News

16. јул

[#Product] You can replace 20–50 wt.% of carbon black in products with only 5 wt.% of TUBALL MATRIX 601 when manufacturing conductive connecting cable sleeve. Easy processing, low viscosity, and no impact on elasticity make graphene nanotube-based concentrate an advanced conductive agent for high-performance products with a longer service life. https://tuball.com/carbon-nanotube-products/matrix/605?utm_source=Facebook&utm_medium=Product+post&utm_campaign=July+16%2724 #LSR #Rubbers #Cables

Read on Facebook

24. новембар

[💡R&D] Novel wear-resistant EPDM elastomer with TUBALL for harsh working environments was announced at SPE: Inspiring Plastics Professionals. Graphene nanotubes create a network in EPDM, enhancing interaction forces within the matrix. This significantly improves wear resistance, which is important for mechanical seals and transmission devices.

Read the article here: https://4spepublications.onlinelibrary.wiley.com/doi/abs/10.1002/pc.27880

Learn more on graphene nanotubes: https://tuball.com/about-tuball?utm_source=Facebook&utm_medium=Post+campaign&utm_campaign=Nov%2724

#EPDM #RandD #elastomer

Read on Facebook

5. септембар

Greetings from Shanghai! We are waiting for you at Rubber Tech to share insights on how the addition of just 0.06% graphene nanotubes boosts rubber performance by adding conductivity and durability while maintaining elasticity.

#RubberTech #GrapheneNanotubes #RubberIndustry

Read on Facebook