TUBALLBATT NMP

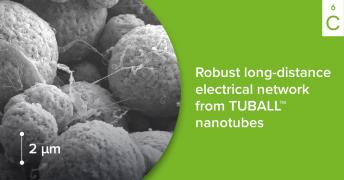

Grâce à leurs propriétés conductrices exceptionnelles les nanotubes de graphène TUBALL™ assurent la conductivité, l'adhérence, la fiabilité, la performance des cycles et la durée de vie de cathodes nécessaires à partir d’une concentration de seulement 0,06 %, ce qui est la meilleure performance sur le marché des additifs. Le dosage standard des additifs conventionnels tels que le MWCNT ou le noir de carbone conducteur est souvent plus élevé de 10 à 50 fois! La concentration ultra-faible de nanotubes TUBALL™ permet aux fabricants de batteries lithium-ion de maximiser l'intensité énergétique des cathodes en augmentant la quantité de matériau actif. Ainsi, dans les matériaux modernes à base de NCM et d'autres matériaux cathodiques, elle peut atteindre 99 %. Avec seulement 100 g de nanotubes de graphène TUBALL™ dans un bloc de batterie de véhicule électrique moderne, il est possible de remplacer 3 à 4 kg de noir de carbone.

Avantages

Thanks to 10–60 times lower loading of conductive additive, up to 98.8% active material content possible in dry electrode

Increased safety due to halved battery resistance increase (DCR)

>50% higher at high discharge rates

Doubled thanks to the bond strength between cathode particles

Documents

Nouvelles